Digital dentistry has been with us for some time now. Long gone are the days of developing x-ray film in dark rooms and viewing them with incandescent bulb-illuminated wall-mount view boxes. Most dental practices today have long joined the world of JPEGs, PNGs, BMPs, and PDFs.

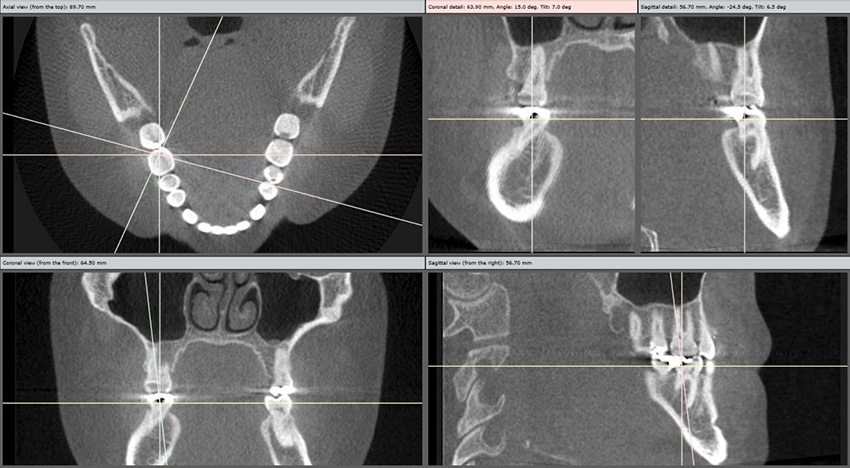

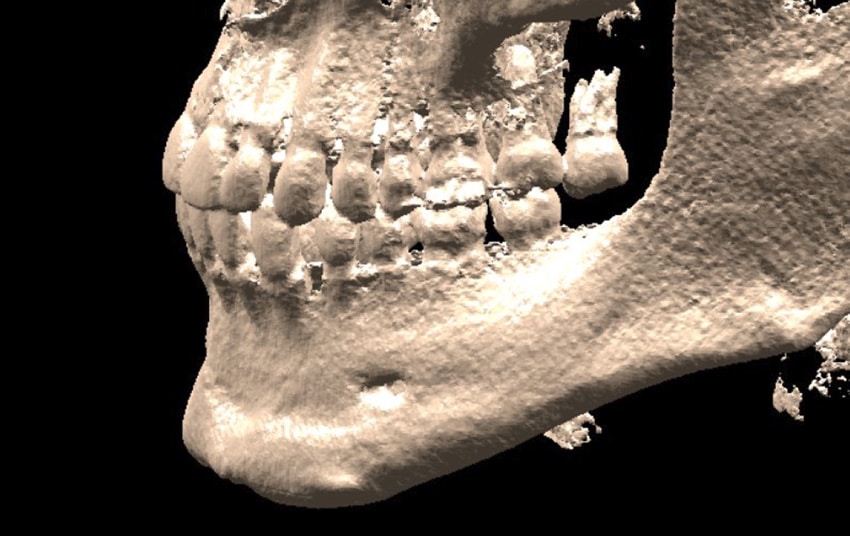

As for 3D dentistry, however, little progress has been made outside of a few specialties like maxillofacial surgery and implantology, where 3D CBCT imaging is a must for a proper diagnosis and treatment planning. The resultant DICOM files, however, are extremely large, complex, and difficult to manage and manipulate, especially in a cloud-hosted imaging system.

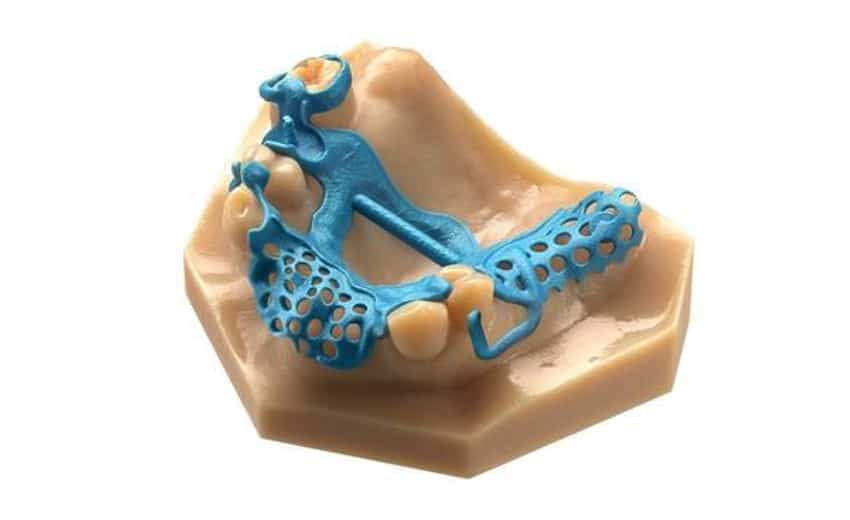

Within recent years, early adopters have started to embrace 3D dentistry via in-office 3D milling (by Cerec, Sinterex, etc.) of crown restorations, inlays, and bridges.

Even when considering the initial investment in equipment, by reducing the total procedure time from 2-3 appointments to a single one, this approach to restorations can increase the practice’s total patient throughput, revenues, and profits all while increasing patient satisfaction as well. These restorations milled in the office can be an order of magnitude more accurate than the conventional lab-fabricated ones, ultimately resulting in a tighter fit and comfort for the patient and a longer restoration life as well.

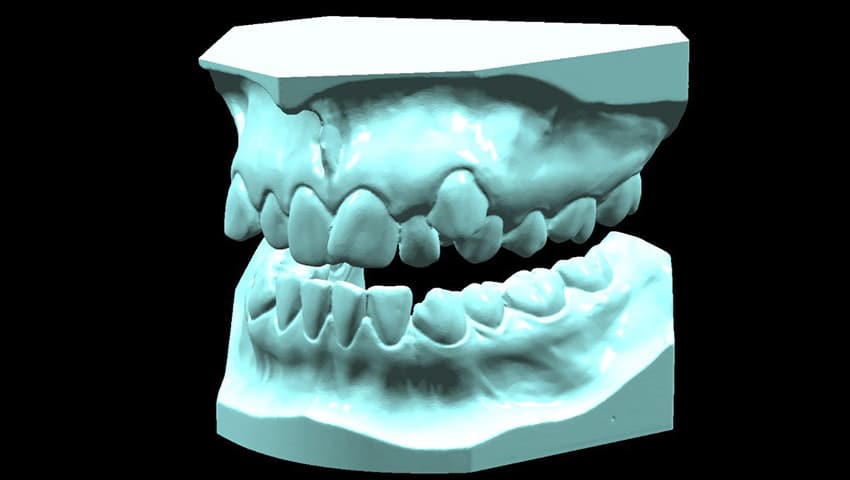

With the advent of increasingly powerful computers and the recent advances in 3D optical scanning and image processing technologies (powderless, fogless, etc.), high resolution impressions can now be taken in 5-10 minutes instead of 40-50 minutes and uploaded directly to a clear aligner service provider for treatment planning and 3D printing of the resultant clear alignment trays. Clear aligners (such as Invisialign, ClearCorrect, etc.) are here to stay for relatively simple crowding, spacing, and malocclusion cases as they offer the patient a better quality of life over the duration of the treatment.

To fulfill all these newly found uses, more and more vendors are rushing to market with better, smaller, and cheaper optical scanners with more and more innovative features such as 3Shape’s Trios portable wireless scanner at the high end and the inexpensive Densys3D at the low end. Most newer models can be driven from a small gaming laptop that can fit well into a crowded dental office in contrast with the first-generation cart-placed ones (like iTero, etc.)

With the ability to export the optical scans as standard STL files, most of these newer models can be used in a variety of applications, and not be limited to just a single use such as taking impressions for clear aligners only. As more and more general-purpose 3D viewing and dental CAD-CAM applications (like BlueSky Plan, etc.) support the STL standard as an input file format, scanners that can export directly to an STL format can be very versatile in a modern dental practice.

Stone models can also be converted into 3D digital STL models for digital viewing and archiving via inexpensive 3D scanners such as AutoScan from Shining3D and others. This can free up a massive amount of space in a traditional dental practice with a long history of taking conventional impressions and having stone models fabricated in a lab, not mentioning the much more rapid location of the right 3D models within the electronic patient’s records.

Printing of any 3D models exported in a STL format can also be done relatively inexpensively in the office via 3D printers such as FormLabs’ Form2 and others. As for printing clear aligners in the office, we are still awaiting the newer 3D-printing materials that will be FDA approved for being worn in-mouth for an extended period of time. Until then, vacuum molding of approved plastic materials and subsequent manual or CMC-driven trimming will still be the only option.

In conclusion, there is a lot of critical mass building now and 3D dentistry is finally coming out of age – pretty much like digital x-ray imaging has started to take over the analog world about 20 years ago.

Will you be ready?